Flange

Flange

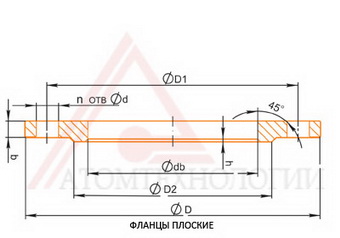

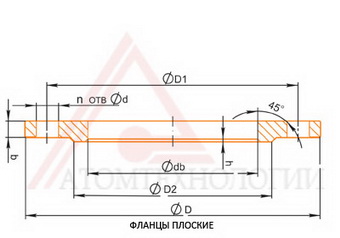

Company “Atomtehnology” LTD produces flanges mainly by forging. Flanges are those elements which are used to connect pipes, they may have the form of a flat disk, a ring, or (infrequently) square frame. Given the nature of the production, according to GOST 12815-80 provided in design to produce round and square flanges. As we know, flat flanges according to GOST 12820-80 have multiple holes for bolts or studs.Owing to these holes in the flanges can be reliably and tightly connect pipelines with low and medium pressure, separate pipes or pipe fittings necessary parts to a particular equipment. For example, they are used when you need to connect all kinds of items traded in different devices and machines. When mounting flanges flat steel as if pushed onto the pipe , and then double- welded weld around the circumference of the pipe. But steel weld flange can be connected with one weld. Only need to connect the collar flange and butt-end of the pipe. Flat flanges are comfortable enough to install and in use.

Stainless steel flanges preferably made of stainless steel alloy, which is characterized by resistance to chemical and physical influences, besides, did not actually fall under the influence of corrosion. Worth to note that the stainless steel flanges completely inert, environmentally friendly, strong, that’s why they can be used in the food industry and health without harming human health. Thus, such flanges do not require additional processing or protective agents in dyeing. That’s why, stainless steel flanges are significantly longer than the product of another metal. Steel flange welded to the ring has two distinct parts: a ring and flange diameter and pressure.

These flanges are very convenient for installation, because the pipe is welded only ring and flange-free, that makes it very easy to connect if necessary through the bolt holes loose flange with the screw holes of the flange pipe fittings. This method is often used for mounting in tight spaces or pipeline repair parts (checks) flanged connections.

If we consider the method of connecting flange sealing surface shape and dimensions, Division of guests, flanges can be divided into the following categories: a) GOST 12820-80 for – flat flanges; b) per GOST 12821-80 – flange collar; c) in accordance with GOST 12822-80-free flange welded on the ring; g)according to GOST 28759.3-90 – flanges for vehicles and vessels. Flanges are widely used stainless steel as individual parts.

They can be bolted or welded to the ends of the parts. And also possible to apply them in the form of separate elements to the shaft of various pipe fittings , hull parts. The sealing surface of the flange depends on the profile of pressure medium and the quality of the gasket material. Consider design features flanges: Material (steel grade), nominal pressure (PN kgf/cm2 ) orifice (DN mm) Housing flange from 1 to 9 (to determine the form of the sealing surface for the gasket ). The material (steel grade). Flanges can be produced from carbon steel, stainless and carbon steels. At this time, the flanges are made of mostly steel grades such as AISI 321, st.09G2S, St20. Those steels can be concluded that stainless steel flanges contain chromium dopant.

For example, standard stainless steels having 12 % to 20 % chromium. In addition, some have also contain alloying elements (molybdenum, nickel, cobalt, titanium , manganese and niobium) that attach the flanges stainless particular characteristic. Provided grades are selected taking into account the further use of flanges in a particular temperature range, reference pressure and transported medium in pipelines.

Away 12816-80 given steel grade requirements for flanges, and the size and structure relatively flat steel welded flanges can be found in the GOST 12820-80. Nominal pressure (PN, kgf/cm2). Nominal pressure (PN) is one of the significant features of the connection flange. Pressure indicator depends on the version of the sealing surface of the flange and its geometric size.

This index can be expressed in units such as: bar, atm ., MPa, Pa and kgf/cm2. To indicate the nominal pressure flange is preferably used in the unit kgf/cm2. It should be noted that the flanges stainless steel (GOST 12820-80) and weld flange (according to GOST 12822-80) is kept nominal pressure of about 25 kg/cm2. But flanges buttwelding (according to GOST 12821-80) can withstand conventional pressure and 200 kgf/cm2. Orifice (DN mm). Orifice (DN) is not the external diameter of the pipe (as one might think), and the section of the pipe (pass) flange, through which flows a particular environment. Mainly produce steel flanges and flange weld with such a nominal diameter (DN): 150mm, 125mm, 100mm. That’s why, produce three allowed suitable designs with different outer diameters for pipes.

Mounting flange dimensions (outer diameter), and the diameter of the bolt hole center (number of holes and their diameters) should be the same size, and respond according to GOST 12820-80. Because of this, with such ordering flanges with port (DN) as 150mm, 125mm, 100mm, you must specify the letter (character), according to which corresponds to the desired diameter of the tubes (Table 1). Table 1.

|

Diametr, mm

|

DN, mm

|

|

А

|

Б

|

В

|

|

152

|

159

|

168

|

150

|

|

133

|

140

|

–

|

125

|

|

108

|

114

|

–

|

100

|

Housing flange. Accordingly, the requirements of GOST 12815-80 stainless steel flanges welded flat, collar and welding ring sealing surface made with performances from I to IX (1-9) with a corresponding mounting dimensions and forms the mating faces of the flanges. It should be noted that different versions of the free flange only admissible only for the ring weld. The most common are flat flanges of the I-th execution. Buy other type flanges are typically needed only in the case if they would be used in extreme conditions or high pressure.

That is why the selection of specific flanges must take into account not only the pressure and diameter, but also figure Housing flange sealing surface. With reference pressure (PN) which is higher than 2.5 MPa (25 kgf/cm2) to ensure excellent sealing systems often use performance flange sealing surface from 2 to 7, inclusive.

Flanges of different versions can be interconnected in such a way: performance under the number I, which has a connecting lug, can be connected with the execution of a number of V (has grooves); execution numbered II, which has a protrusion with execution III (a cavity); performance at number IV ( has spikes ) – may be connected with the execution of V (has grooves); performance under number VI ( made gasket lens ) combined with the performance of VI; performance under the number VII ( manufactured gasket with oval cross section ) – with the same performance VII; performance under the number VIII ( a spike ) was combined with the performance IX ( a groove ), the obligatory use fluoroplastic lining.

We will establish an example for a symbol flange weld steel flat performance I, which has a connecting projection , nominal bore (DN) of 200 mm, nominal pressure (PN) of 0.25 MPa (2.5 kgf / cm 2) is made of steel grade according to GOST 12820-80 09G2C. So, we get the following entry-flange 1-200-2,5-09 G2S – GOST 12820-80.

The first type of performance are flat welded steel flanges, which are manufactured in accordance with GOST 12820-80 and they are mostly intended to be used in a temperature range from -70 ° C up to 300 ° C. To flanges steel, stainless steel, welded to the flange ring, and dissimilar performances could provide strength and integrity of a particular compound of the junction of different ways, using the coupling protrusions, hollows, grooves. For example, are very popular stainless steel flanges, which are highly resistant to corrosion, and are made from high-alloy steel AISI 321.

These flanges stainless steel produced by the “hot stamping”, so certainly subjected to heat treatment. That’s why, these flanges are used in industries where desirable exceptional durability and strength of the pipe material to corrosion. Flanges can be used as independent fasteners and flanges together with a washer, gasket and others.

Steel flanges used not only with the particular pipe installation equipment, but also for fixing together. Actually, integrity and strength of pipelines depends on what quality flanges. Stainless Steel Flanges according to GOST 12820-80 flat used to securely connect piping components with low and medium pressure. This flange is pushed over the flat pipe, and then welded thereto double weld. Flange steel flat weld made in accordance with GOST 12820 – 80harakterizuetsya sufficiently broad line diameters from 15 mm to 800 mm. In flanged pipe used in the case where there is a need in releasable pipe. Or when connected to a flanged pipe fittings, flanges measuring devices and equipment having a flange. Use flanges. If the pressure is equal to or below 4 MT is allowed planar mounting flanges. In another case it is necessary to use flanges butt welded, and those having a hollow sealing surface or protrusions.

Certainly, the price of stainless steel flanges and joints for pipeline is much higher than for the same flanges made of carbon steel.But note – this difference in price is fully recouped reliability and durability of compounds made by stainless steel flanges . Flanges stainless steel very well tolerate aggressive action environment resistant to high salinity and humidity, temperature fluctuations perfectly maintained.

These flanges are used in a production environment with a gas, carbon, cold or hot water, oil, non-corrosive liquids. The fact that stainless steel flanges are constantly used in industry, tied to oil, says that these special flange requires reliability.

That’s why one of the main advantages of the flange connection is that it is not hard to understand (or replace) if necessary, and then sealed together. It is known that the flange joint tightness depends on how tight seal to the mirror flange and on which a sealing surface of the structure . Predominantly in a particular pipe flanges used with the sealing surface which can be flat or can have grooves spines, dimples or protrusions or have a coupling protrusion, or such that a suitable gear gasket. Depending on the temperature and nominal flanges are distinguished by material and type, and mounting dimensions. Note – instead of GOST 9938-62, GOST 1255-67, GOST 12828-67 and GOST 12827-67 GOST 12820-80 introduced.

Price

Фланец плоский ГОСТ 12820-80

|

ду/ру, мм

|

сталь 20

|

сталь 09Г2С

|

сталь 12Х18Н10Т

|

сталь 10Х17Н13М2Т

|

| |

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

| |

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

Цена/грн

|

|

15

|

21

|

24

|

29

|

26

|

29

|

35

|

120

|

156

|

180

|

180

|

210

|

260

|

|

20

|

30

|

35

|

40

|

37

|

44

|

50

|

160

|

190

|

230

|

230

|

270

|

340

|

|

25

|

40

|

47

|

54

|

48

|

55

|

63

|

210

|

250

|

300

|

270

|

320

|

380

|

|

32

|

45

|

50

|

59

|

52

|

62

|

72

|

310

|

390

|

430

|

390

|

450

|

540

|

|

40

|

50

|

56

|

63

|

57

|

68

|

79

|

390

|

450

|

530

|

480

|

550

|

650

|

|

50

|

58

|

63

|

72

|

65

|

78

|

90

|

470

|

580

|

690

|

540

|

640

|

780

|

|

65

|

75

|

82

|

97

|

86

|

105

|

120

|

610

|

720

|

820

|

870

|

960

|

1100

|

|

80

|

90

|

98

|

110

|

105

|

125

|

140

|

730

|

840

|

980

|

970

|

1100

|

1250

|

|

100

|

110

|

125

|

140

|

140

|

170

|

190

|

870

|

1000

|

1200

|

1100

|

1200

|

1370

|

|

125

|

145

|

170

|

190

|

180

|

210

|

250

|

1130

|

1330

|

1520

|

1380

|

1560

|

1750

|

|

150

|

170

|

185

|

210

|

195

|

240

|

280

|

1340

|

1610

|

1920

|

1780

|

1950

|

2200

|

|

200

|

210

|

230

|

265

|

240

|

280

|

320

|

1780

|

2100

|

2400

|

2250

|

2500

|

2900

|

|

250

|

290

|

330

|

390

|

350

|

410

|

450

|

2450

|

2700

|

3200

|

2800

|

3200

|

3600

|

|

300

|

350

|

380

|

450

|

400

|

470

|

520

|

2700

|

2870

|

3340

|

3000

|

3300

|

3800

|

|

350

|

490

|

540

|

620

|

560

|

670

|

750

|

3560

|

4100

|

4900

|

4300

|

4900

|

5400

|

|

400

|

640

|

720

|

850

|

740

|

890

|

970

|

4980

|

5870

|

6970

|

5900

|

6400

|

7500

|

|

500

|

850

|

960

|

1100

|

990

|

1190

|

1410

|

5400

|

6700

|

7890

|

6800

|

7600

|

8800

|

|

600

|

1120

|

1230

|

1450

|

1240

|

1500

|

1820

|

8900

|

10500

|

12300

|

10400

|

12400

|

14300

|

|

700

|

1430

|

1790

|

1890

|

1820

|

2160

|

2540

|

12400

|

14900

|

17800

|

14300

|

16700

|

18700

|

|

800

|

1830

|

2100

|

2400

|

2200

|

2650

|

3120

|

17200

|

21200

|

24890

|

20800

|

23900

|

26000

|

|

900

|

2400

|

2640

|

2890

|

2750

|

3240

|

3500

|

21500

|

26200

|

29700

|

23700

|

28700

|

31500

|

|

1000

|

3400

|

3780

|

4100

|

3900

|

4650

|

4960

|

26700

|

31200

|

37200

|

32100

|

35100

|

39000

|

|

1200

|

4100

|

4500

|

4800

|

4600

|

5520

|

5890

|

48000

|

57100

|

65800

|

59600

|

64000

|

72000

|

| |

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

| |

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

|

ду/ру, мм

|

сталь 20

|

сталь 09Г2С

|

сталь 12Х18Н10Т

|

сталь 10Х17Н13М2Т

|

Фланец воротниковый ГОСТ 12821-80

|

ду/ру, мм

|

сталь 20

|

сталь 09Г2С

|

сталь 12Х18Н10Т

|

сталь 10Х17Н13М2Т

|

| |

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

| |

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

|

15

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50

|

|

|

|

|

|

|

|

|

|

|

|

|

|

65

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100

|

|

|

|

|

|

|

|

|

|

|

|

|

|

125

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200

|

|

|

|

|

|

|

|

|

|

|

|

|

|

250

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300

|

|

|

|

|

|

|

|

|

|

|

|

|

|

350

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1000

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1200

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

Цена

|

| |

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

10

|

16

|

25

|

|

ду/ру, мм

|

сталь 20

|

сталь 09Г2С

|

сталь 12Х18Н10Т

|

сталь 10Х17Н13М2Т

|